It’s official – the first customer to fly a new E-Jet E2 is Widerøes Flyveselskap of Norway. The airline will take delivery of an E190-E2 in the first half of 2018. I can think of no better company than Scandinavia’s largest regional carrier to have the distinction. And for good reason.

Widerøe has been flying in some of the most demanding conditions on the planet for 83 years. That’s tremendous technical and operational experience. But the airline is not facing its new aircraft introduction alone. We’ve worked hard to deliver the E2 family with extremely high reliability and systems maturity at entry into service. And we’ll be side-by-side with Widerøe to ensure its new aircraft perform right from day one.

Being the first operator of any new airplane always has an element of risk. I say “new” airplane because 75% of the components and systems on the E2s are new as a direct result of incorporating new technology to reduce costs and increase reliability. Teething problems are common but I’m confident Widerøes E2s will be few and minor. After all, we’ve spent years focusing on key areas to specifically reduce entry-into-service risk. Without getting too technical, a few of those areas are:

Cross-Technology Philosophy

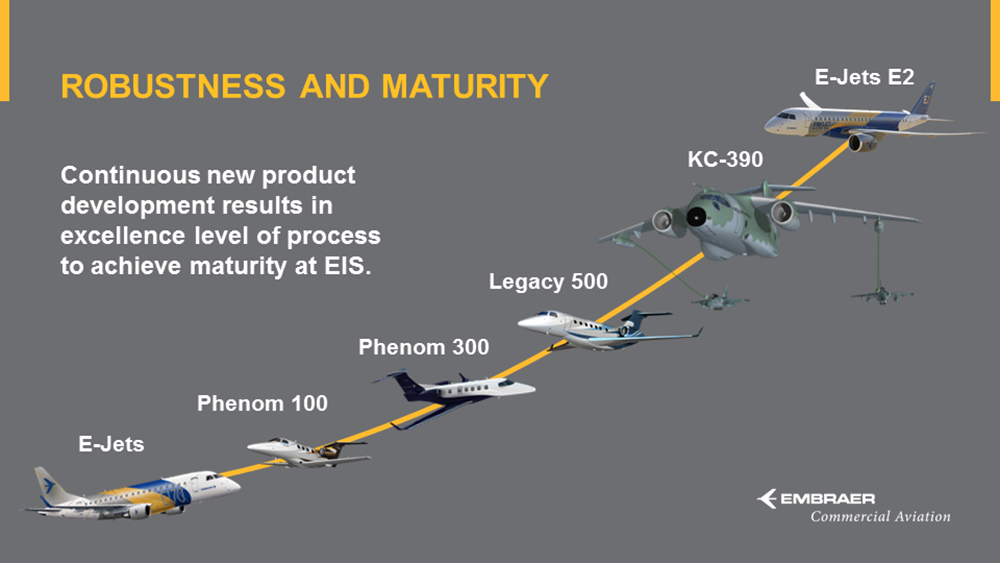

No other OEM has designed as many new airplanes in the last 20 years as Embraer. We learned a lot from developing the Phenoms, the Legacy 450/500 and the KC-390, and took EIS readiness know-how from those executive and defense aircraft and applied it to the E2 program. That experience is helping many of the same engineers who worked on the first-generation E-Jets birth the second generation.

Exhaustive Simulations, Tests & Screening

After delivering more than 1,300 aircraft, we’ve seen how the airplanes have performed in different airline applications and operating environments with more than 100 operators. Our teams pored over data from some 17 million flight hours on the current world fleet. Their reports identified E2 components that we then subjected to High Accelerated Life Testing and High Accelerated Stress Screening, two initiatives that directly impact reliability.

We also conducted in excess of 30,000 digital simulations and virtual and real ground tests – an extraordinary number – to identify potential system failures and propose remedies well before a prototype E2 even took to the sky. To us, it wasn’t surprising that we were able to dispatch the first E2 to the Farnborough Air Show just two months after roll out.

Supply Chain Management

The E2 supply chain is now much more vertically integrated. This has given us better control over big items like the landing gears and wings. We also became the main integrator for flight control laws, something we could finally do after the experience we gained from the Legacy 500 and KC-390. Suppliers can make us or break us. That’s why we engaged them in the E2 Maturity Program from the very start. All of this means that we’ll be able to respond to customer needs faster and develop quick solutions for field issues.

Every launch airline naturally expects technical snags with a new airplane. Of course, the devil is always in the details. But by dedicating so many human and technical resources so early in the program, I know that the first E2s will be reliable right from the start.

After all, building new airplanes is something we’ve been doing for nearly 50 years.