Photo credit: James Bell Photography

As commercial aviation rebuilds from the impact of the pandemic, there’s a new focus on more environmentally responsible airplanes. Most airlines have purged their oldest aircraft types. OEMs are ramping up designs for electric and hydrogen-fuelled powerplants. Carriers are pledging net zero emissions goals by 2050. The industry is on a path to green.

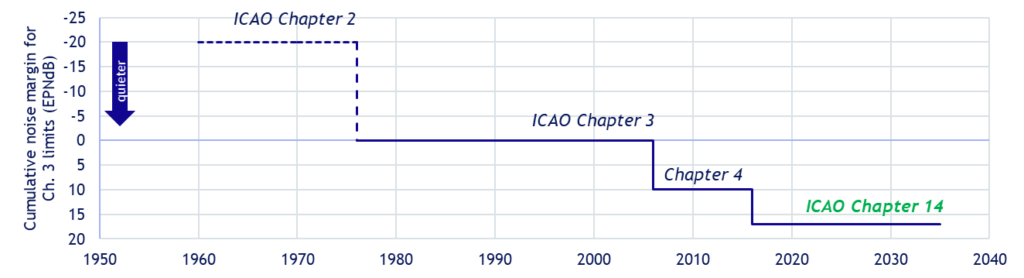

Reductions to NOX and CO2 emissions aren’t the only targets for reductions. Airports and residents living near them are demanding new aircraft to be quieter. Aircraft certified under EASA and the FAA that conform to ICAO’s stringent Chapter 14 limits will be welcome at the world’s most noise-sensitive airports. And they’ll incur lower take-off and landing charges.

ICAO’s noise limits have become more restrictive over the past 40 years:

From the start, Embraer’s E-Jets E2s were designed to comply with ICAO’s most rigorous Chapter 14 noise limits.

Quieter by Design

With the objective of producing the quietest single-aisle aircraft on the market, Embraer enlisted the help of experts from Brazil’s University of São Paulo’s São Carlos School of Engineering, the São Paulo State Research Support Foundation, the Institute for Aeronautics Technology, Twente University in Enschede, the Netherlands Aerospace Centre, and Germany’s Deutsches Zentrum für Luft- und Raumfahrt.

Dubbed projects Silent Aircraft, Silence, and Silent Approach, teams developed tools to predict sources of noise and reduce noise generation during the development of the E2 program. It was the third largest aero-acoustic study in the world when it began in 2010.

Since the E2’s PW1900G ultra high-bypass ratio geared turbofan engine was already quiet, the focus turned to the new E2 structure to find further ways to reduce noise. Air friction from the wings and landing gear during take-off, descent, approach and landing also generate noise.

Engineers simulated the air stream created both virtually and physically by a scale model in a wind tunnel at São Carlos’ aerodynamics lab. Giant fans in the test tunnel produce winds up to 180 km/h. The tunnel also has ultra-sensitive microphones to detect noise sources on the aircraft structure. From their analysis, the engineers made adjustments until they found the ideal geometry of the wing and its high-lift devices that generated the lowest noise.

Embraer also improved the aerodynamics of the fuselage by streamlining or reducing the size of antennas and exterior components and adding landing gear doors.

The new noise levels were confirmed by further tests in large wind tunnels in the Netherlands and Germany, and with real aircraft at Embraer’s test facility at Gavião Peixoto.

E190-E2 wind tunnel test at DNW’s facility in the Netherlands.

Sensors measure E190-E2 take-off noise levels at Gavião Peixoto

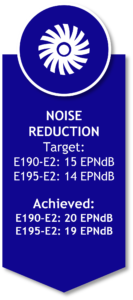

The certified Effective Perceived Noise

decibel (EPNdB) values for the E190-E2

and E195-E2 were a remarkable 5 EPNdB

lower than Embraer’s original

aggressive targets.

Certified to be Even Quieter

When the E2s entered service, their noise levels were more than 17 EPNdBs lower than ICAO’s Chapter 4 cumulative limit and were already in compliance with the stricter Chapter 14 limit. Recertification to Chapter 14 in June 2020 required a routine submission of test documentation since the airplanes needed no physical modifications.

Similarly, Embraer’s first-generation E-Jets entered service certified with noise levels more than 10 EPNdBs lower than ICAO’s Chapter 3 cumulative limit. That healthy margin qualified them to be recertified to ICAO’s more stringent Chapter 4 in March of this year.

Just How Quiet are the E2s?

The E2s are extremely quiet. In fact, they generate the same noise as some turboprops, which are in general smaller and lighter. Among other single-aisle jets, the E2s are the quietest. Comparing certified cumulative noise levels at take-off, the E190-E2, for example, is 10 EPNdBs quieter than the A321. To the human ear, that equates to about 50% less perceived noise. When compared to the A220-100, the E195-E2 is 11% quieter. That may not seem like a big number, but that EPNdB reduction is a huge engineering achievement. The difference between the ICAO chapters is narrowing because of this kind of technical advancement.

A Smaller Footprint Cuts Noise and Cost

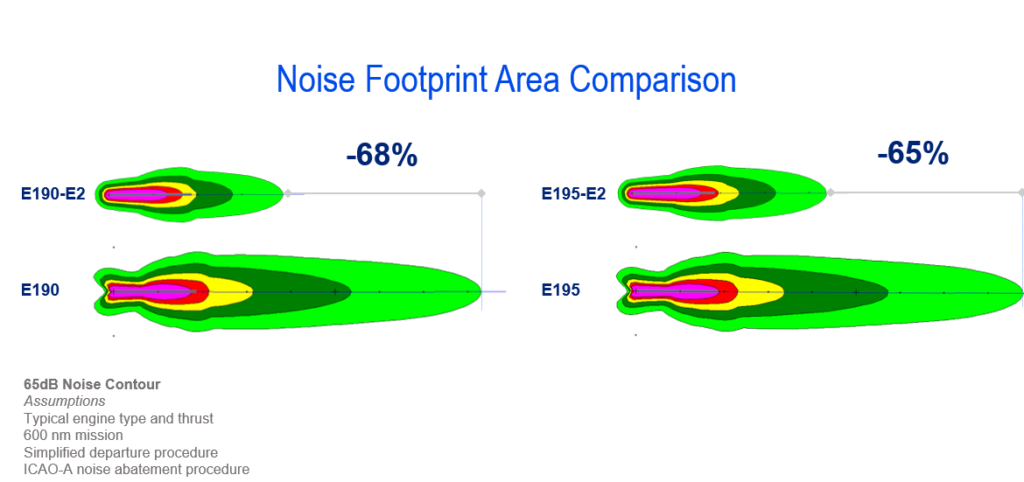

The new, quieter E2s have up to 68% smaller noise footprints than their first-generation versions. That’s good news for airport neighbours and even better news for airlines that are subject to noise and emissions surcharges that comprise aircraft movement fees at airports.

Those fees could be more costly as aviation gets greener. If approved by Sweden’s parliament, Stockholm Arlanda Airport and Göteborg Landvetter Airport plan to calculate take-off and landing fees based on emissions. Aircraft that are more efficient, generate fewer emissions, and use biofuels would incur lower charges. The initiative is a first in Europe and if successful, could apply to other airports in Sweden.

Today, however, the noise recertifications to Chapter 4 for the E190 and Chapter 14 for the E190-E2 are already saving airlines money. At London Heathrow, for example, take-off and landing charges for the E190 are 63% lower (a savings of some ₤3,700 compared to the previous Chapter 3 charge), and 72% lower for the E190-E2, a savings of ₤1,200 compared to the previous Chapter 4 charge.

Quieter E-Jets mean they’re more welcome by passengers, airlines, and the world’s most noise-sensitive airports.